Flexibility and high quality are self-evident for us – but alongside them, production efficiency has always been at the core of our strategy. At Jouka, we have continuously developed our processes to serve our customers faster and more cost-effectively, without compromising on quality.

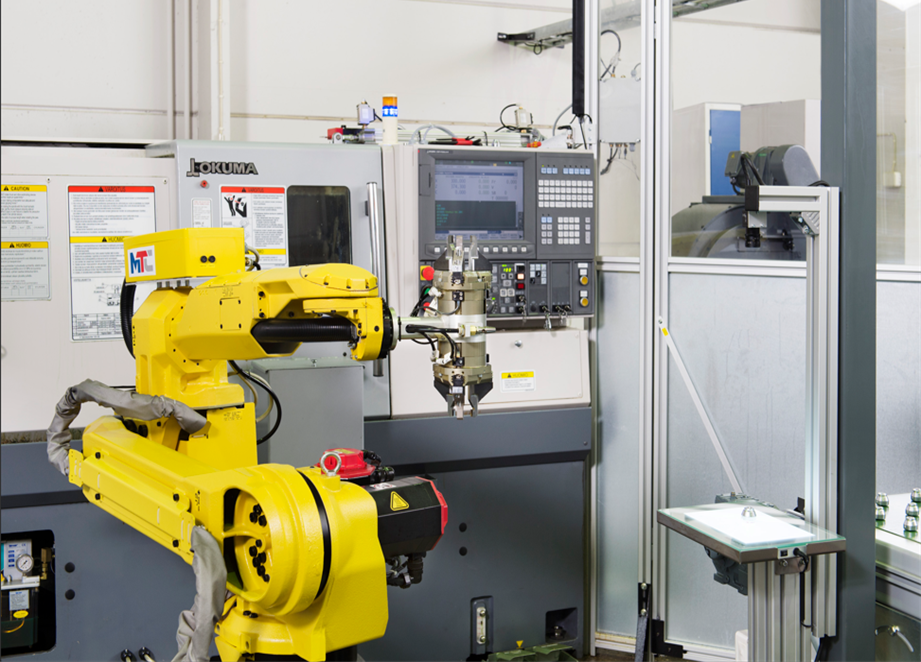

The next step is an investment in three new robotic cells and an automated leakage testing device. Earlier this year, we also introduced an automatic band saw for the initial stages of production. Together, these investments take our efficiency, quality, and delivery reliability to a new level.

Robotics takes development to the next level

The introduction of robotics is a natural continuation of our long-term development efforts. These investments not only improve production efficiency but also strengthen our ability to meet the challenges of the future.

“We have been improving our production for a long time, but the limitation has been the sufficiency of a single shift. Our cost-benefit analysis showed that the volumes and products are ideal for automated cells, which can be run unmanned when needed. Robotics will increase productivity, control labour costs, and bring long-term savings,” says production manager Aki Saarenmaa.

These investments are not isolated updates, but part of a strategic development path that also supports improved occupational safety.

From repetitive routines to more meaningful tasks

Robotics significantly changes everyday work at Jouka. Job roles are becoming more diverse, shifting towards programming and operating machines – making work more engaging and deepening professional skills. By automating larger production series, employees’ time is freed up for demanding small-batch production, which is one of our key competitive advantages.

After a two-day robotics training, our staff shared their impressions with enthusiasm:

“Exciting and interesting at the same time.”

“Great to have the chance to learn something new.”

“Physical strain is reduced and throughput times improve.”

“It fits well with today’s world, and Jouka’s competitiveness is maintained.”

Looking ahead – more quality and reliability

In addition to robotics, we have also invested in the automation of quality control. The new leakage testing device measures the tightness of every single valve, ensuring that any potential leaks are detected already during production. This allows us to keep our promises of delivery reliability and high quality.

Robotics is a natural extension of our long-term development. With these investments, we will be able to provide even higher-quality and more advanced solutions.

This is a major leap forward – and at the same time, a continuation of the work we have been doing for decades: valves you can trust.