Jouka vacuum ball valves have been specifically designed and tested for vacuum use, making them ideal for food industry applications. Many of our customers have chosen our products for their reliability in various transfer systems.

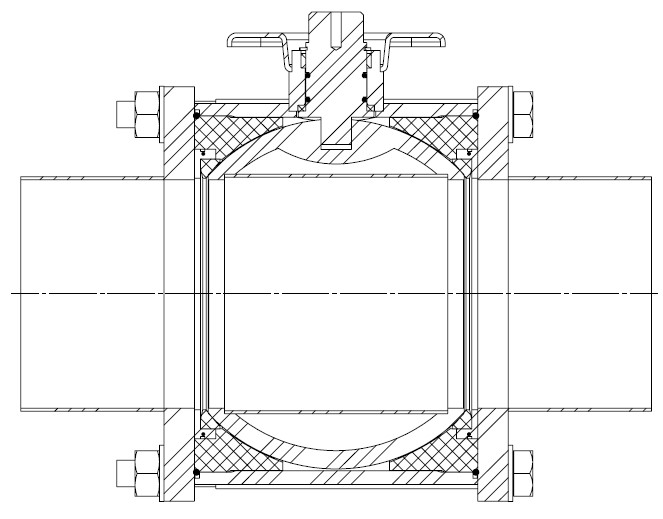

Our ball valves stand out because of their design, optimized for high hygiene requirements. The flushing capability and special filler ball seats ensure that the valves are easily cleaned, and they prevent the accumulation of medium inside the valve. An added feature is that a cleaning sequence can be integrated into our valves, allowing for efficient internal flushing.

Applications:

- Food industry

- Pneumatic vacuum conveying

Benefits:

- Filling seals prevent medium residues inside the valve

- Flushing connections allow for cleaning the inside of the valve

- The valve has been tested and works well under vacuum conditions

Special features:

- 1/2″ flushing/rinsing interface to clean the valve body internally

- All valves are stainless steel (AISI304L, AISI316L)

- Actuator and limit switch option

- Welded or flanged joints

- Filler ball seats to prevent particles inside the valve body

- Nitrogen-tested valves for special vacuum requirements

- Sizes from DN25 to DN150

Contact us

Contact our experts to learn more about our product and its customization possibilities. Our team is dedicated to providing solutions tailored to your specific needs. Jouka ball valves are a trusted choice – and we want to ensure that together we find the best solution for your application.