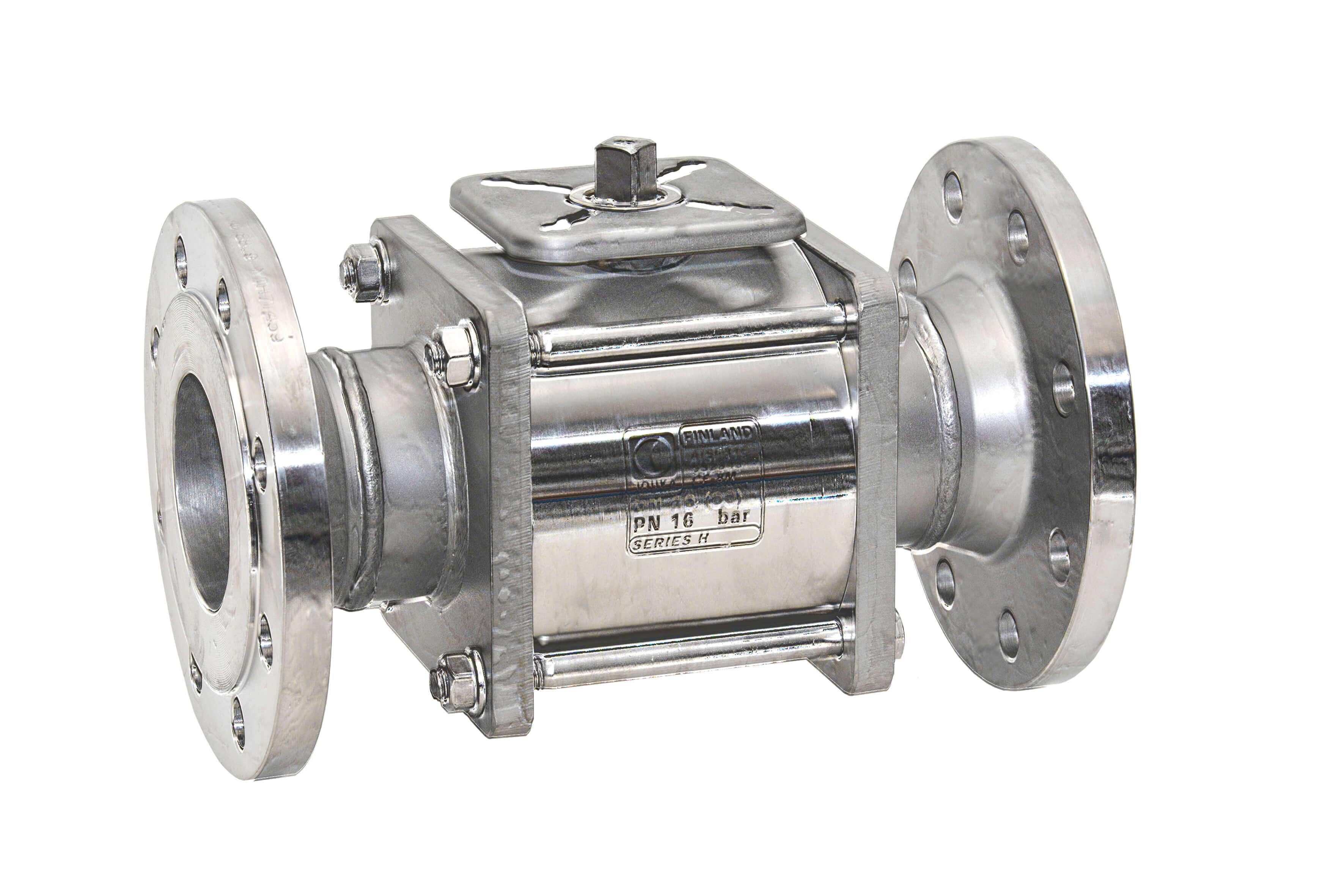

When your application requires excellent corrosion resistance or safety in chemical processes, Jouka’s stainless steel ball valves offer a reliable and long-lasting solution. You can choose between AISI 316L or AISI 304L material – depending on your process conditions.

Stainless steel valves are suitable for applications with corrosive mediums or external corrosive environments. Examples include the chemical industry, paper industry, mechanical engineering, and automotive applications. Additionally, for food industry use, we can equip stainless steel valves with FDA-approved O-rings and ball seals.

Key features and applications of stainless steell ball valves

- Excellent chemical resistance

- Flexible customization options

- Easy to automate with actuators

- Temperature range:

- With standard O-rings: –55 °C to +180 °C

- With special or metal seats: up to +300 °C

- Suitable for corrosive media and environments

- Available with ATEX-certified options for explosive atmospheres

- Standardized F-mounting surface for fast and secure actuator installation (square shaft)

Suitable for Industries:

- Chemical industry

- Pulp and paper industry

- Mechanical engineering

- Vehicle systems

- Food industry

- Explosion-hazard areas (ATEX)

How to choose between 316L and 304L?

316L / EN 1.4404 – stainless steel

- Excellent all-round material for demanding conditions

- Strong corrosion resistance across various environments

- Suitable for many types of media

- Very fast availability directly from Jouka’s warehouse

304L / EN 1.4307 – stainless steel

- Avoids dissimilar material joints in stainless steel pipelines

- Offers even better corrosion resistance than 316L in nitric acid and black liquor lines

- Also available quickly from our stock

Looking for a tailored solution for your application?

Contact our sales team – we’re happy to help.

Contact us: