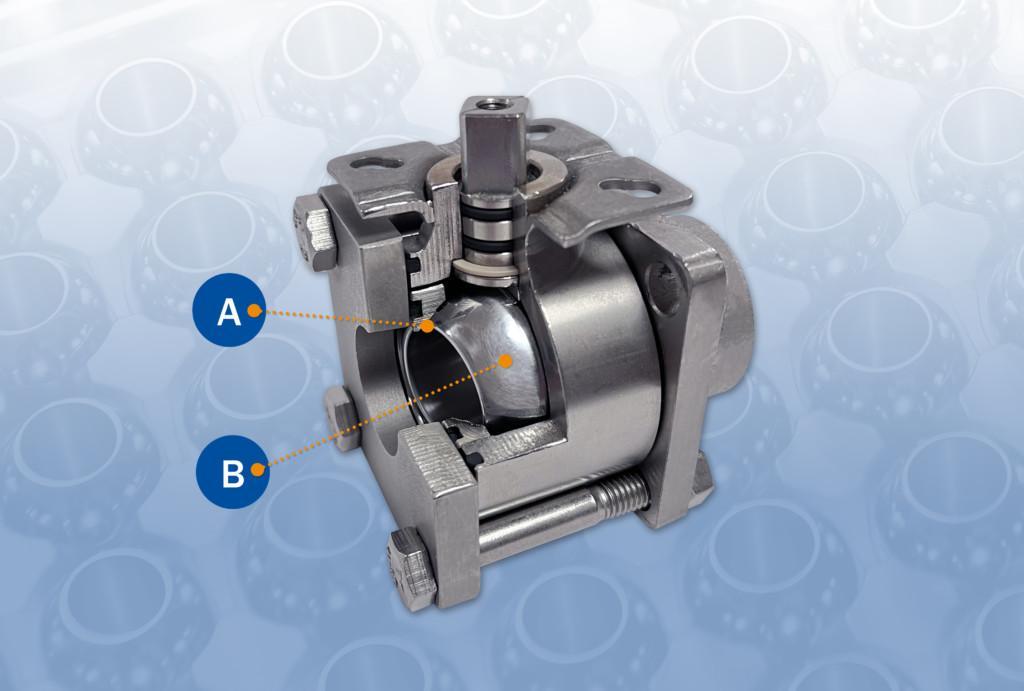

The metal seat ball valve is specifically developed for fiber-containing mediums, making it suitable for the high temperatures and abrasive mediums in the paper industry. The valve’s hard-chromed ball adds durability against abrasion and heat. The ball and the metal seats are matched to each other to ensure optimal leakage tightness using a special process called lapping.

Advantages of metal seats

- Excellent resistance to mechanical wear, making them suitable for mediums containing solid particles.

- Top-tier leakage rate, Rate B (standard EN 12266-1).

- Suitable for high temperatures (up to +300°C).

- The hard surface of the hard-chromed ball repels dirt and allows for the lapping of the ball and seats. Additionally, the hard-chromed ball has good durability. Metal seats feature a scraper groove that keeps the ball clean when opening and closing the valve.

- Metal seats are available for Jouka’s standard valves. Learn more about our ball valves here.

- Stock materials: HST (AISI316L / 1.4404), RST (304L / EN 1.4307), Duplex (EN 1.4462), and Super Duplex (EN 1.4410).

- Wide range of sizes: DN10-DN200.

B: A hard chromed ball enables the pairing. In addition, wear resistance and is also improved.

Leakage tightness of metal seats

A valve with metal seats can never be made 100% leakage proof. We process the ball and seats with a special process called lapping. In the lapping process, the ball and metal seats are paired to achieve the lowest possible leakage. Through lapping, a leakage rate B (EN 12266-1 ) is achieved, where, for example, a DN25 valve is allowed to leak only 0.45 ml/min and a DN100 valve 1.8 ml/min. The leakage is practically very minimal, but it is important to consider this, especially when the medium is highly toxic or easily flammable gas.

Ota yhteyttä